Radwaste management: deep boreholes

Into the deep

25 March 2010The lower reaches of a borehole drilled 5km (3mi) into the earth’s crust represents an interesting alternative location for high-level radioactive waste compared to mined repositories at much lesser depths. The first deep borehole performance assessment and dose estimate has been carried out. By Bill W. Arnold, Peter N. Swift, Patrick V. Brady, S. Andrew Orrell, and Geoff A. Freeze

The potential technical and cost advantages of deep borehole disposal have become more apparent over time. Drilling technology for petroleum and geothermal production has improved, resulting in lower costs and greater reliability for the construction of deep boreholes. Deep borehole disposal, characterization and excavation costs should scale approximately linearly with waste inventory: small inventories require fewer boreholes; large inventories require more boreholes. Characterization of near-surface geology and hydrology required for deep borehole disposal should be less extensive and costly than for shallower mined repositories because of the greater isolation of waste in deep boreholes. Conditions favourable for deep borehole disposal exist at many locations, particularly on geologically stable continental cratons. A system of regional deep borehole disposal sites could possibly help address waste management equity issues and perhaps transportation concerns.

In 1957 the U.S. National Academy of Sciences Committee on Waste Disposal considered both deep borehole disposal of radioactive waste (in liquid form) and mined storage of radioactive waste in a positive light [1]. The intervening half-century has seen high-level waste and spent nuclear fuel disposal efforts in the United States and other nations focus primarily on mined repositories. Nonetheless, evaluations of the deep borehole disposal concept have periodically continued in several countries (for example, [2-7]).

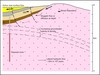

The deep borehole disposal concept consists of drilling a borehole into crystalline basement rock (typically granite) to a depth of about 5000m, emplacing waste canisters containing spent nuclear fuel or vitrified radioactive waste from reprocessing in the lower 2000m of the borehole, and sealing the upper 3000m of the borehole. The concept is illustrated in Figure 1, showing the borehole disposal depth relative to the typical depth for mined repositories of several hundred meters. Waster in the deep borehole disposal system is several times deeper than for typical mined repositories, resulting in greater natural isolation from the surface and near-surface environment.

The viability and safety of the deep borehole disposal concept are supported by several factors. Crystalline basement rocks are relatively common at depths of 2000 to 5000m in the United States and many other countries, suggesting that numerous appropriate sites exist. Low permeability and high salinity in the deep continental crystalline basement at many locations suggest extremely limited interaction with shallow fresh groundwater resources, which is the most likely pathway for human exposure. The density stratification of groundwater would also oppose thermally induced groundwater convection from the waste to the shallow subsurface, as shown in Figure 1. Geochemically reducing conditions in the deep subsurface limit the solubility and enhance the sorption of many radionuclides in the waste, leading to limited mobility.

Preliminary estimates for deep borehole disposal of the entire projected waste inventory through 2030 from the current U. S. fleet of nuclear reactors suggest a need for a total of about 950 boreholes, with a total cost that could be less than a mined repository disposal system at Yucca Mountain [8].

The legal and regulatory framework governing the disposal of high-level radioactive waste in the U. S. and other countries is oriented toward mined geological disposal and likely would need to be revised to implement deep borehole disposal. In particular, regulations specific to the potential retrieval of waste would need to be modified to reflect the more permanent disposal nature of a deep borehole disposal system. Although retrievability would be maintained during emplacement operations, waste may not be fully recoverable once the borehole has been sealed, and deep borehole systems may not be the best choice if permanent and irreversible disposal is not intended.

Technical baseline

A relatively simple nominal design for the deep borehole disposal system has been evaluated in this article. The borehole would be drilled and cased in stages with the diameter decreasing from about 122cm at the surface to about 44cm in the disposal interval. Emplacing intact spent fuel assemblages, without pre-consolidation, is one of the simplest approaches to borehole disposal [9], and is the one considered here. A canister made of standard oilfield casing 5m tall and having an inner diameter of 32cm and an outside diameter of 34cm could hold one pressurized water reactor (PWR) assembly. End-caps would be welded on after assemblies had been inserted into the canisters. Crushing of underlying canisters during the operational period would be prevented by bridge plugs in the borehole. The canisters would be surrounded by bentonite slurry and the upper 3000m of the borehole would be sealed by a combination of compacted bentonite packs, asphalt, and concrete plug.

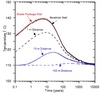

Temperatures within the borehole and the host rock were simulated using a horizontal, two-dimensional model of thermal conduction [9]. The model uses the heat output curve for a single average PWR fuel assembly that has been aged for 25 years and representative values for the thermal conductivity of granite. Simulated temperature histories shown in Figure 2 indicate that temperature increases in the vicinity of the borehole are not large, do not persist for long periods of time, and drop off rapidly with distance from the borehole. Temperatures at the borehole wall peak at about 30°C higher than the ambient temperature of the host rock within ten years of waste emplacement.

Coupled thermal-hydrologic modeling was performed to evaluate the three-dimensional movement of groundwater induced by waste heat. These simulations assumed that the disturbed zone in the granite around the borehole would have a higher permeability than the surrounding host rock, forming a ‘chimney’ for potential circulation of fluid. Results indicate upward vertical flow in the borehole disturbed zone driven primarily by thermal expansion of groundwater, not by significant free convection. Upward flow of about 1.5cm/year was simulated to occur for about 200 years after emplacement at the top of the waste disposal zone. Lesser upward flow of up to 0.35cm/year occurs for about 600 years at a location 1000m above the waste (still 2000m below the ground surface).

The geochemical behaviour (solubility, sorption, colloidal behaviour, etc.) of the projected waste inventory in the deep borehole environment sets limits on the stability of the uranium spent fuel matrix and on radionuclide transport to the biosphere. For the purposes of estimating radionuclide solubilities and sorption coefficients, a reasonable salinity is ~2-3mol/L, pHs are 8-9 and the system Eh is approx. -300mV [10]. The relatively low solubility of UO2 under deep borehole conditions, estimated to be on the order of 1x10-8 mol/L, will favour stabilization of spent fuel rods. The solubilities of isotopes of americium (Am), actinium (Ac), curium (Cm), neptunium (Np), protactinium (Pa), plutonium (Pu), technetium (Tc), and thorium (Th) are even lower than that of uranium – sometimes several orders of magnitude lower – suggesting that aqueous releases of these radionuclides would be small. Most radionuclides released from the bottoms of deep boreholes adsorb to basement rocks, to overlying sediments, and to the bentonite used to seal the borehole. Sorbing radionuclides would move hundreds to thousands of times more slowly than any groundwater movement. Notable exceptions are iodine-129 and carbon-14, which would be highly soluble and experience little or no sorption on to the host rock. Colloids do not remain suspended in groundwater at high salinity and would not be a significant factor in radionuclide transport.

Performance Assessment

A preliminary quantitative performance assessment was conducted for the deep borehole disposal of spent nuclear fuel assemblies using a simplified and conservative representation of the system [8]. The release scenario analyzed in this performance assessment involved transport of dissolved radionuclides by hydrologic flow up the zone of enhanced permeability associated with the borehole and into a shallow fresh water aquifer from which they are pumped to the biosphere. The performance assessment included 31 key radionuclides. Several features, events, and processes (including nuclear criticality, molecular diffusion, and hydrofracturing of the host rock by thermal expansion of water) were excluded from consideration in the performance assessment based on separate preliminary analyses.

The performance assessment analysis is for a single borehole containing 400 PWR assemblies at a depth of 3000-5000m below the surface. It is assumed that the waste canisters corrode quickly and that dissolved concentrations of radionuclides within the borehole are governed by solubility limits of solid oxide phases. Thermally-driven flow within and above the disposal zone was applied, based on the coupled thermal-hydrologic modeling described above.

Radionuclide transport for 1000m up the borehole was calculated using a one-dimensional analytical solution, including the effects of advection, dispersion, decay, and sorption. It was conservatively assumed that the upper 2000m of the subsurface contains fresh groundwater and that a water supply well for 1000 people was pumped directly above the disposal zone. A dilution factor of 3x107 and delay time of about 8000 years for radionuclide transport associated with the well pumping was simulated in a separate three-dimensional model. Radiological dose to a hypothetical person using water from the pumping well was calculated using biosphere dose conversion factors from the Yucca Mountain Project.

Results of the preliminary performance assessment indicated a peak dose to an individual using the contaminated groundwater of 1.4x10-12 mSv/year (1.4x10-10 mrem/year). This calculated dose is for a single borehole; however, the result should scale approximately linearly for multiple boreholes. The only radionuclide contributing to the calculated dose was iodine-129, which has high solubility and is nonsorbing. The peak dose was calculated to occur about 8200 years after waste emplacement. For comparison, the IAEA recommends a post-closure dose limit of 0.3mSv/year (30 mrem/year) for geological disposal facilities [11]. Although uncertainty in these results was not formally evaluated, the preliminary performance assessment used reasonable parameters for the calculations and some conservative assumptions in the conceptual model of the disposal system.

Author Info:

Bill W. Arnold, Peter N. Swift, Patrick V. Brady, S. Andrew Orrell, and Geoff A. Freeze, Sandia National Laboratories, P.O. BOX 5800, MS-1369. Albuquerque, NM 87185-1369. Sandia is a multiprogram laboratory operated by Sandia Corporation, a Lockheed Martin Company, for the United States Department of Energy’s National Nuclear Security Administration under contract DE-AC04-94AL85000.

References have been omitted but are available on www.neimagazine.com/borehole

Related ArticlesDeep borehole disposal (DBD) methods Looking down the bore Deep boreholes - references