Fourth tier of inner containment completed at Akkuyu 3 as more equipment installed at unit 1

26 October 2023

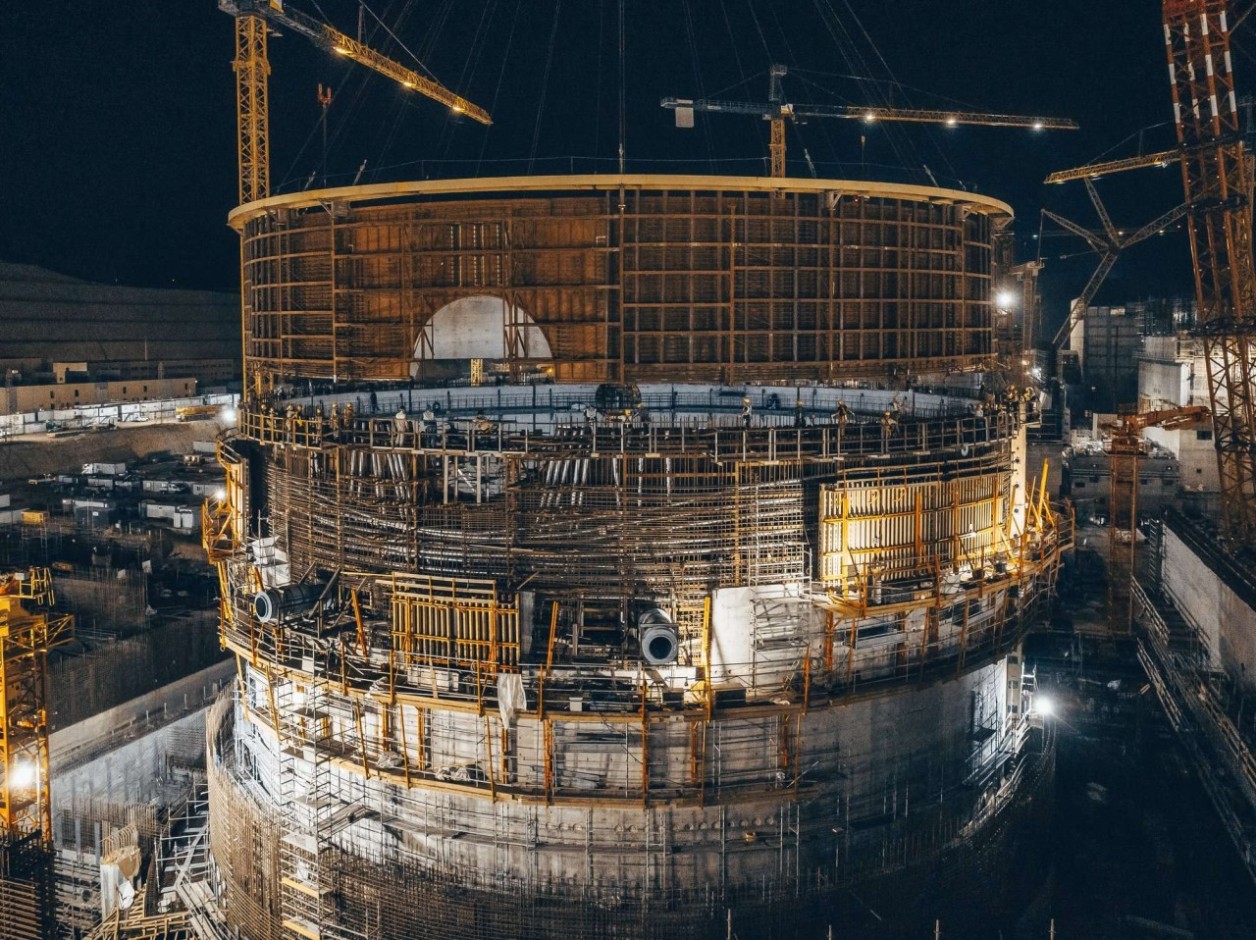

The fourth tier of the internal containment ((VZO)) has been completed in the reactor building of unit 3 at the Akkuyu NPP under construction in Turkiye. The VZO, which ensures the protection and tightness of the reactor compartment, consists of a steel cladding and a special concrete mixture, which is produced directly at the Akkuyu NPP construction site.

The fourth tier of the internal containment ((VZO)) has been completed in the reactor building of unit 3 at the Akkuyu NPP under construction in Turkiye. The VZO, which ensures the protection and tightness of the reactor compartment, consists of a steel cladding and a special concrete mixture, which is produced directly at the Akkuyu NPP construction site.

The reactor buildings at the Akkuyu NPP power units are equipped with double containment. The outer protective shell is formed from reinforced concrete and designed to withstand extreme external influences including magnitude 9 earthquakes, tsunamis, hurricanes, as well as their combinations.

Akkuyu, Turkiye's first NPP, will eventually host four Russian-designed VVER-1200 reactors. The pouring of first concrete for unit 1 took place in April 2018, for unit 2 in June 2020, for unit 3 in March 2021, and for unit 4 in July 2022. Completion of unit 1 is expected in the third quarter of 2023. Rosatom is constructing the reactors according to a build-own-operate model. To date, the project is fully funded by the Russian side. However, Rosatom has the right to sell a share of up to 49% in the project to other investors.

Under the terms of the Intergovernmental Agreement between the Russian Federation and the Republic of Turkiye, commissioning of unit 1 should take place within seven years after receiving all necessary permits. As the construction licence for unit 1 was issued in 2018, commissioning is formally due by 2025. However, every effort is being made to ensure that it will be ready in time for Turkiye’s centenary celebrations in 2023.

Meanwhile, the Central Design & Technological Institute (JSC CPTI, part of Rosatom’s fuel company TVEL) has supplied the first component of the refuelling machine equipment at Akkuyu 1. The first element of the machine sent to the Akkuyu NPP was the rail track. In combination with the bridge, this mechanism ensures the movement of the machine to a given coordinate. It is designed in such a way as to exclude uncontrolled movements of equipment during  seismic impacts, blackouts and other emergency situations. The length of the rails is more than 26 metres, the track width is more than 8 metres.

seismic impacts, blackouts and other emergency situations. The length of the rails is more than 26 metres, the track width is more than 8 metres.

The refuelling machine is one of the most complex systems in the reactor island combining mechanical, lifting and electrical devices and a control system. Its installation requires extreme accuracy. The permissible deviation of the upper and side components of the rail track for a length of 3000 mm is no more than 0.3 mm, the slope of the track should not exceed 0.15 mm per 1000 mm of length.

“Taking into account the specific features of the Akkuyu NPP construction site, the project turned out to be unique. We are successfully moving towards the delivery of a full set of equipment for the first unit, which is planned for the end of 2023. Our contract includes the supply of similar equipment for all four power units,” commented Mikhail Tarasov, General Director of CPTI JSC.

Images courtesy of Akkuyu Nukleer