The Volgodonsk branch of AEM-Technologies (part of Rosatom’s mechanical engineering division Atomenergomash) has assembled the reactor vessel (RPV) with internals that has been manufactured for unit 5 of India’s Kudankulam NPP.

The Volgodonsk branch of AEM-Technologies (part of Rosatom’s mechanical engineering division Atomenergomash) has assembled the reactor vessel (RPV) with internals that has been manufactured for unit 5 of India’s Kudankulam NPP.

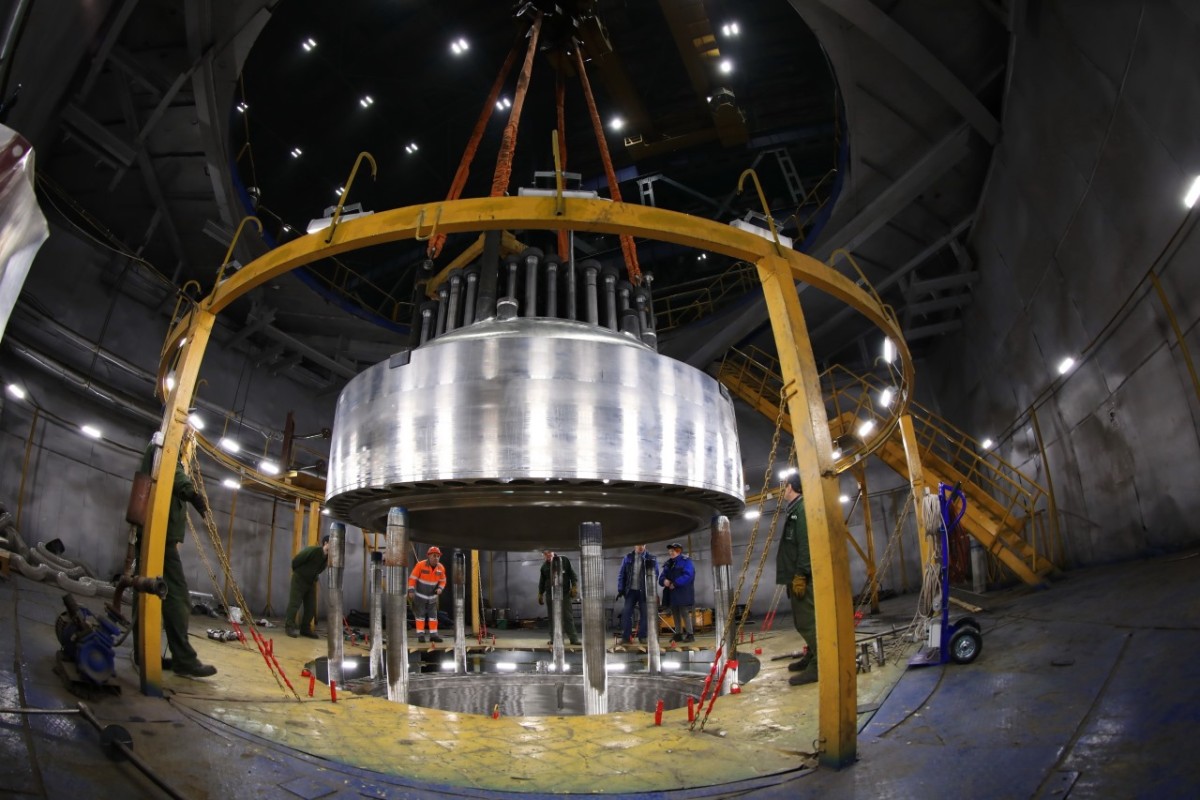

The control assembly was carried out using an underground caisson stand. First, specialists using a crane with a lifting capacity of 600 tons installed the 11-metre VVER-1000 RPV in its position. Next, one by one, a 10-metre internal shaft weighing 73 tons, a baffle of 38 tons, and a block of protective pipes weighing 68 tons were lowered inside. The nuclear reactor was then closed with a standard lid. The total weight of the assembled product was 603 tons.

During the assembly, the employees installed dowels and fasteners on the RPV and attached fixtures for centring the reactor lid. A control assembly, in which the products completely replicate their design position, significantly reduces the time and simplifies the installation of the reactor at the NPP construction site.

The reactor is a vertical cylindrical vessel with an elliptical bottom, inside which the active zone and internal devices are located. From above, the equipment is hermetically sealed with a lid with drives for the mechanisms and control & protection equipment installed on it, as well as branch pipes for the output of cables and sensors of in-reactor control.

Kudankulam NPP in the state of Tamil Nadu in southern India will comprise six units with VVER-1000 reactors with an installed capacity of 6000 MWe. Units 1&2 (Phase I) began commercial operation in 2014 and 2017. Construction of units 3&4 (Phase II) and 5&6 (Phase III) is underway. Based on an intergovernmental agreement between India and Russia signed in 1988, Nuclear Power Corporation of India Limited (NPCIL) is building four VVER-1000 units (3-6) at Kudankulam with Russian assistance. The expected completion date for units 3&4 is 2023.

Image: View of the reactor pressure vessel assembly as the head is positioned (courtesy of Atomenergomash)