Radwaste | Disposal

The self-disposal option

1 August 2012Self-descending tungsten capsules could be used to dispose of heat-generating high-level waste tens of kilometers below the Earth’s surface. By Michael Ojovan, Pavel Poluektov and Vladimir Kascheev

The self-disposal option for heat-generating radioactive waste such as spent fuel, high level reprocessing waste or spent sealed radioactive sources was considered in the 1970s as a viable alternative disposal option by both Department of Energy in the USA and Atomic Industry Ministry in the USSR. The method has been analyzed in some detail, with laboratory experiments reported [1, 2].

Deep self-disposal involves loading radioactive waste together with a powerful heat-generating radionuclide into a sealed metal (tungsten) capsule and placing it at the bottom of a shallow borehole. Due to radiogenic heat generation, the capsule will melt surrounding rock and self-descend. Estimates suggest that extreme depths of up to 100 km can be reached using this method of disposal.

Melting of the rock by a hot capsule is possible if the temperature of the surface of the capsule is higher than the melting temperature of the rock, and the average density of the capsule is higher than the specific mass of the rock.

It is typically assumed that a spherical capsule with radius R is heated as a result of radioactive decay of a nuclide up to a temperature higher than the melting temperature of the rock. Because of the intense penetrating radiation, the distribution of heat sources within the capsule can be considered uniform over the entire volume of the capsule. If the capsule is made of a material that ensures good absorption of radiation, practically all of the energy released by the radioactive decay will be used for heating. The total power of heat released, Qtot, then depends on the mass, M, of the heat-generating radionuclides and the specific heat release, Qm, of the nuclide:

![]()

Numerical values are presented in Table 1: Heat generating radionuclides for several radionuclides whose emissions could provide enough heat for a self-sinking capsule. These radionuclides are among the main components of radioactive waste. Note that the decay products of these radionuclides are nongaseous, which avoids possible complications due to excess pressure buildup in the capsule.

The specific heat release due to the decay of radionuclides within a capsule of radius R is then

![]()

The condition for self-sinking of the capsule as a result of melting through the surrounding rock is given by the Byalko ratio [1, 2]:

![]()

where ? is the thermal conductivity; Tm is the melting temperature; and Tr is the temperature of the rock far from capsule. Capsules with a specific power of heat release less than the qth threshold do not melt the surrounding rock and, consequently, remain stationary. According to [1, 2], motion of the capsule in a partly cracked (fissured) rock is possible if the surface temperature of the capsule is higher than the melting temperature by some threshold value. This effect can be taken into account by an appropriate correction to the melting temperature Tm.

Specifically, for granite rocks containing ~0.6% water, Tm = 950 °? [4], the threshold thermal power is qth = 16.2 kW/m3.

The total threshold power of a 1m diameter spherical self-sinking capsule is ~8.5 kW. The minimum amounts of Co-60 and Cs-137 necessary for self-sinking of that capsule into a granitic formation are 0.5 kg and 14 kg, respectively. Hence the total volume of capsule (520 L) enables loading of a large amount of waste in addition to the radionuclides that provide the heat required for rock melting. Note that a sphere of Co-60 metal with an activity of 3.85x1018 Bq, which would yield ~1635 kW of heating power (that is, one hundred times above threshold), would only be about 0.3 m in diameter.

Capsule design

The temperatures required for effective rock melting are well in excess of 1000°C, increasing with pressure, and ideally the capsule needs to withstand temperatures in excess of 2000°C. Ceramic materials, although suitably refractory, tend to be poor heat conductors and would overheat, thus limiting thermal loading of capsules, the descent rates and depth. The capsule should therefore be made of metal. It was proposed to use tungsten for this purpose [1, 2]. Tungsten melts at 3410°C, has a specific gravity of 19.3, and is relatively inexpensive. It is also expected to have a low corrosion rate in silicate melts at high temperatures and pressures, as well as low oxygen fugacities. These characteristics suit the conditions that would prevail during descent through the crust and mantle.

The capsule wall needs to be strong and thick enough to withstand corrosion and abrasion during descent. It must also be able to absorb the radiation from the heat source to ensure efficient heating. Abrasion during sinking through the melted rock is unlikely to be significant, but most metals do corrode by reaction with silicate liquids at high temperature. The minimum wall thickness, d, needed for adequate absorption of ß and ?-radiation is ~ 0.1 m (Figure 1).

Self-descending speed and distance

The gradual sinking of a capsule to increasingly deeper layers by melting rock can be approximated by numerical methods. The time of motion of a capsule in rock can be determined quite accurately. Indeed, the power of thermal sources decreases with time exponentially, q(t)=q(0)exp(-?t), where q(0) is the initial specific power of the sources, ? is the decay constant ? = 0.693/?1/2 , and ?1/2 is the half-life of the radionuclide. The self-sinking capsule stops when the threshold specific power is reached. Consequently, the time of motion of the capsule is given by:

![]()

For t > t the capsule can no longer melt the rock in its path, and comes to a halt.

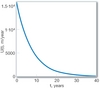

The velocity at which the capsule sinks can be estimated analytically. As shown in Figure 2, initial descending velocities are remarkably high and comparable with conventional rotary drilling of scientific boreholes. The capsule would reach the Mohorovic?i´c discontinuity in less than a half of a year [3].

Due to natural decay of radionuclides, the heat power decreases until it becomes so low that the threshold specific power is reached. Estimates show that a 1m diameter tungsten capsule heated up by Co-60 (total activity 104 MCi) will move for 41.2 years, reaching a final depth of 120 km.

Operational considerations

Self-disposal does not require complex and expensive disposal facilities and provides a minimal footprint used only at operational stage. It also has an extremely high proliferation resistance. Moreover, the utilisation of heat generated by relatively short-lived radionuclides diminishes the environmental uncertainties of self-disposal, thereby increasing the safety of the concept.

Capsules can be launched from the seabed as well as from intermediate-depth or deep boreholes. Loading and weld sealing of capsule with radioactive sources can be done directly before launching, hence standard transport methods could be utilised [Figure 3].

Capsules have a very limited Earth’s disturbing volume (~m3) and footprint area (~m2). They utilise accessible materials of a very small volume (~0.5 m^3). Cobalt-60 is a readily available radionuclide, manufactured by neutron irradiation of metallic cobalt and widely used by industry, medicine and research in the form of sealed radioactive sources (SRS). Spent SRS can be utilized in the self-disposal capsules, rather than new ones.

Capsule descent could be tracked using detection of the acoustic signals generated by melting and solidification (vitrification and crystallisation) of the rocks around and above the capsule [4] (Figure 4).

Alternatively or in addition, adding a mixture of Ra-226 and Be to the active part of the capsule would provide an intensive source of neutron radiation through nuclear reaction (a,n) which enables continuous irradiation of rocks during the capsule’s descent. Registration of signals from the capsule by several coupled detectors would provide permanent information on capsule motion as well as on the geological composition of the deep interior of the earth. Capsules could even be emplaced at given depths to provide information about underground motions, which would be particularly useful in seismically-active regions for monitoring earthquakes.

The self-disposal concept is still far from actual implementation and this article is rather theoretical. Many questions of both a technical and operational safety nature should be carefully considered prior to implementation. Nevertheless the self-disposal concept looks promising for very deep and super-deep (for example, more than 5 km) disposal of the most hazardous heat-generating waste.

Author Info:

Michael Ojovan, Immobilisation Science Laboratory (ISL), University of Sheffield, UK. Pavel Poluektov and Vladimir Kascheev, A.A. Bochvar Institute of Inorganic Materials (VNIINM), Moscow, Russia.

The authors would like to acknowledge useful discussions with Sergey M. Stishov, Vladimir A. Trofimov, Vladimir N. Sobolev, Greg Mayer, Russell Hemley and Jesse Ausubel.

References

[1] M. Ojovan, V. Kascheev, P. Poluektov. Self-disposal option for highly-radioactive waste reconsidered. Mater. Res.Soc. Symp. Proc. 1475, 429-434 (2012).

[2] M.I. Ojovan, V.A. Kascheev, P.P. Poluektov. Self-disposal option for heat-generating waste. ICEM2011-59182 (7 p.).Proc. 14th Int. Conf. Envir. Remed. and Rad. Waste Manag. ICEM2011, September 25-29, 2011, Reims, France, ASME (2011).

[3] Executive summary: "Mantle Frontier" Workshop. Scientific Drilling, 11, 51-55 (2011).

[4] L.M. Spasova, M.I. Ojovan, F.G.F. Gibb. Acoustic emission on melting/solidification of natural granite simulating verydeep waste disposal. Nuclear Engineering and Design, 248, 329-339 (2012).