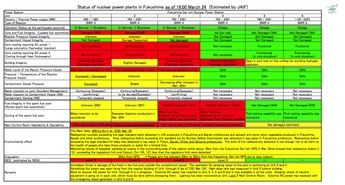

An engineering analysis of unit 1 has shown that recently-detected temperature increases do not threaten the integrity of containment.

The work suggests that even at 400°C, almost three times design-basis temperature, reactor containment strength is about more than double currently imposed stress (including its own weight), so structural integrity is maintained. After increasing unit 1 core cooling functionality, TEPCO decided to decrease injection volume, because of concerns that increasing injection volume would increase pressure inside containment, according to Japan Atomic Industrial Forum.

In other work at the site, power has reached units 2, 4, 5&6, where pre-energising functional checks continue. Lights are now on in the main control rooms of units 1 and 3.

Today, workers began injecting seawater into the spent fuel pool of unit 3 using the fuel pool cooling and filtering (clean up) system. Unit 4 spent fuel pool spraying with the concrete pump continued.

Gray smoke was observed at unit 3 in the afternoon of 23 March. Although unit 3 reactor, reactor containment and immediate surroundings remained constant, workers were evacuated as a precaution. There was no sign of smoke at about midnight 23 March. A steam-like vapour was seen rising from units 1-4 at 7:00 am 24 March; no further information is currently available.

Unit 5's residual heat removal system pump for the reactor has tripped (stopped) on 23 March, and is currently being repaired. A backup pump was due to be installed today. TEPCO said that current water temperature trends suggest that the water will remain below boiling point until the backup starts.